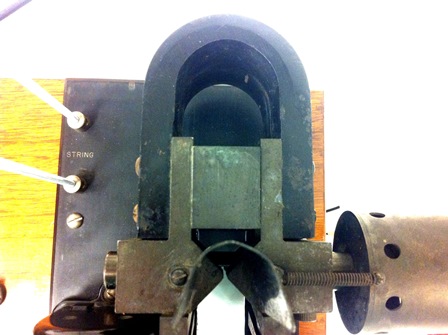

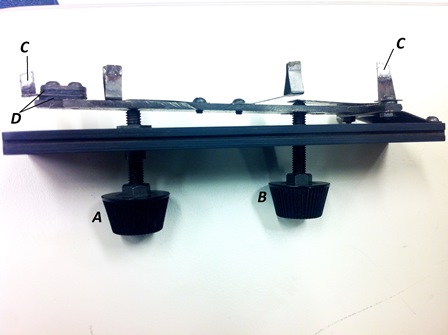

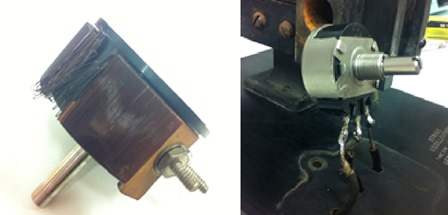

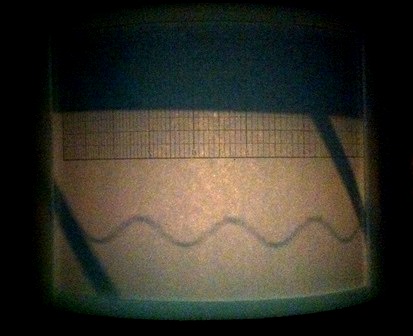

String Oscillogragh, first offered by General Radio in 1928, is a device that enables one to observe waveform of an electrical current in real time. This is accomplished by the following implementations. A very fine tungsten wire is positioned in a magnetic field supplied by a permanent magnet. When an electrical current flows through the wire, the wire will get deflected where the displacement of deflection is proportional to the amplitude of applied current. The string, being suspended in a beam of a powerful lamp, will then cast a shadow of itself upon an arc screen. Before the shadow strikes the screen, it will get reflected from an octagonal non-synchronous mirror, which rotates about an axis parallel to the line of string’s vibration, and be given an additional displacement that is proportional to time. As a result, string oscillograph converts waveform of electrical current into mechanical vibration, which is represented by spots of shadows well spread over the screen, eventually reproducing the waveform of the current which can be easily observed and studied.

For full description, please refer to the file attached below.

Pictures of Different Waveforms Displayed

_________________________________________________

Pictures of String Oscillograph