Professor Littman Introduces Bill Becker, and students introduce themselves:

Students introduce themselves and the various teams and activities they are involved in on campus.

Electrical (Diego and Preston): Worked with real time ultimator of automator and spark plug. They also cleaned a few parts of the headlamp assembly.

Bottom End (Ali W and Hudson): Finished cleaning everything and are now figuring out a way to make the display of the clutch easy to read.

Frame Team (Viduir and Catherine): Polishing the fenders right now. Cleaned underneath and polished the top of one fender. They are finishing the top of the fender this class.

Gaskets and fasteners (Jim and Micah): Worked on carburetor, finished putting it back together and put it onto another bike to test to see if it worked. It retained 0 of the fuel and it all flooded out

Top End (Parker and Chris): Worked on taking apart engine of the 62 bike and taking apart the bottom end and taking the flywheel off.

Bottom End (Jamie and Oscar): Take out flywheel, split the case

Fork (Izzy and Alex): Finished cleaning the fork, took apart throttle and put it back on handle bars. Painted more coats of paint on the triple tree assembly.

Wheels (Aly, Grace, and Jenny): Finished cleaning all the spokes and are now working on finishing cleaning the nipples.

Electrical (Diego and Preston): Worked with real time ultimator of automator and spark plug. They also cleaned a few parts of the headlamp assembly.

————–

Bill Becker: He is a retired architect with a degree in Business Administration. He also has degree in Architecture from Case Western Reserve University. He later went on to study at the University of Pennsylvania. His firm he had started up was later acquired by a huge architectural firm.

He talks about Volosoul x’s that are made in France.

We need to understand physics of mass and motion to understand the wheel.

Influence on mass: dynamic forces (movement), acceleration, braking, turning, gravity

Weight helps because you don’t have all this mass you have to stop

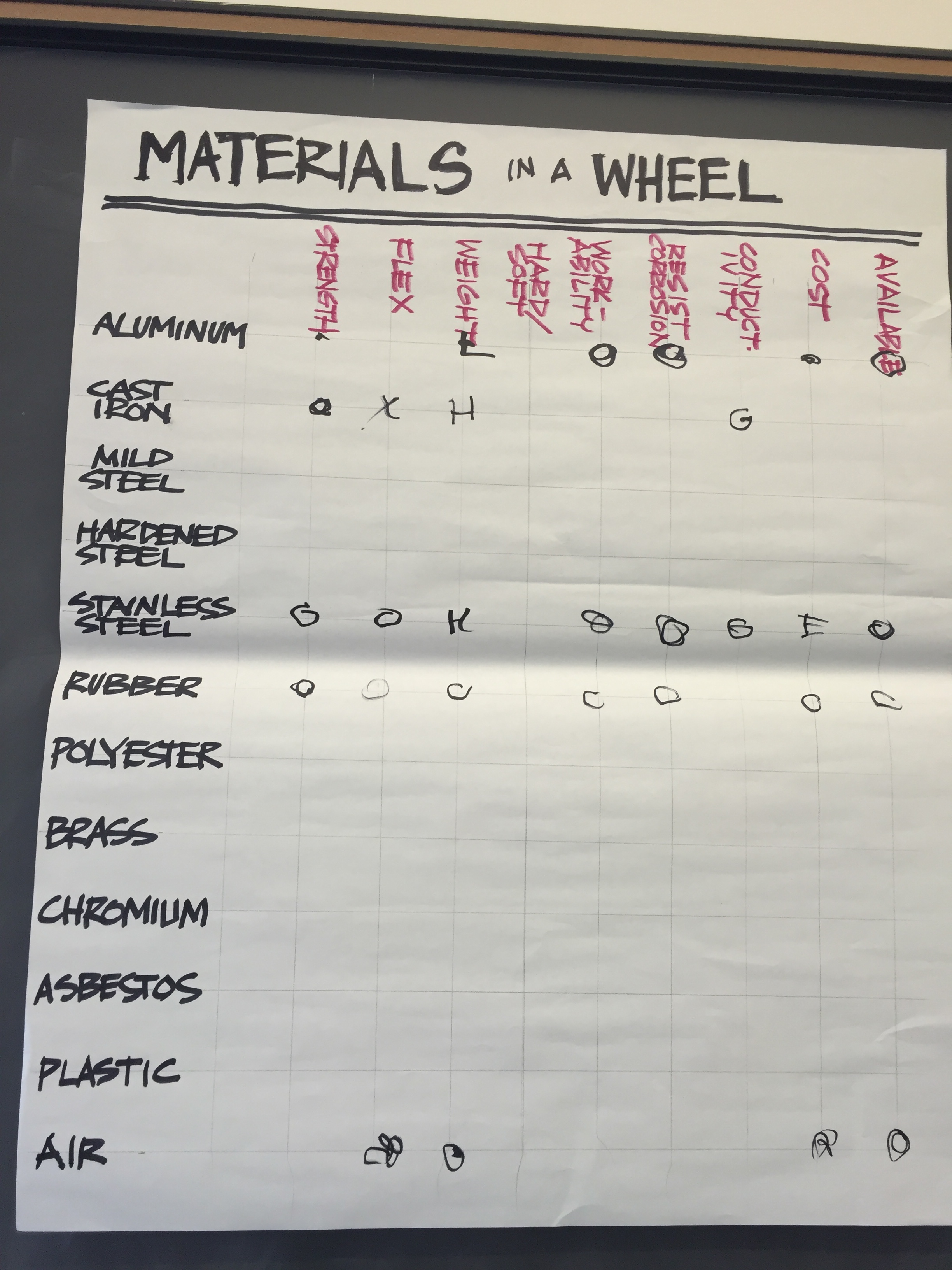

12 materials that are made into a wheel: aluminum, cast iron, mild steel (rims, spokes), hardened steel – ball bearings, stainless steel, rubber, polyester, brass, chrome.

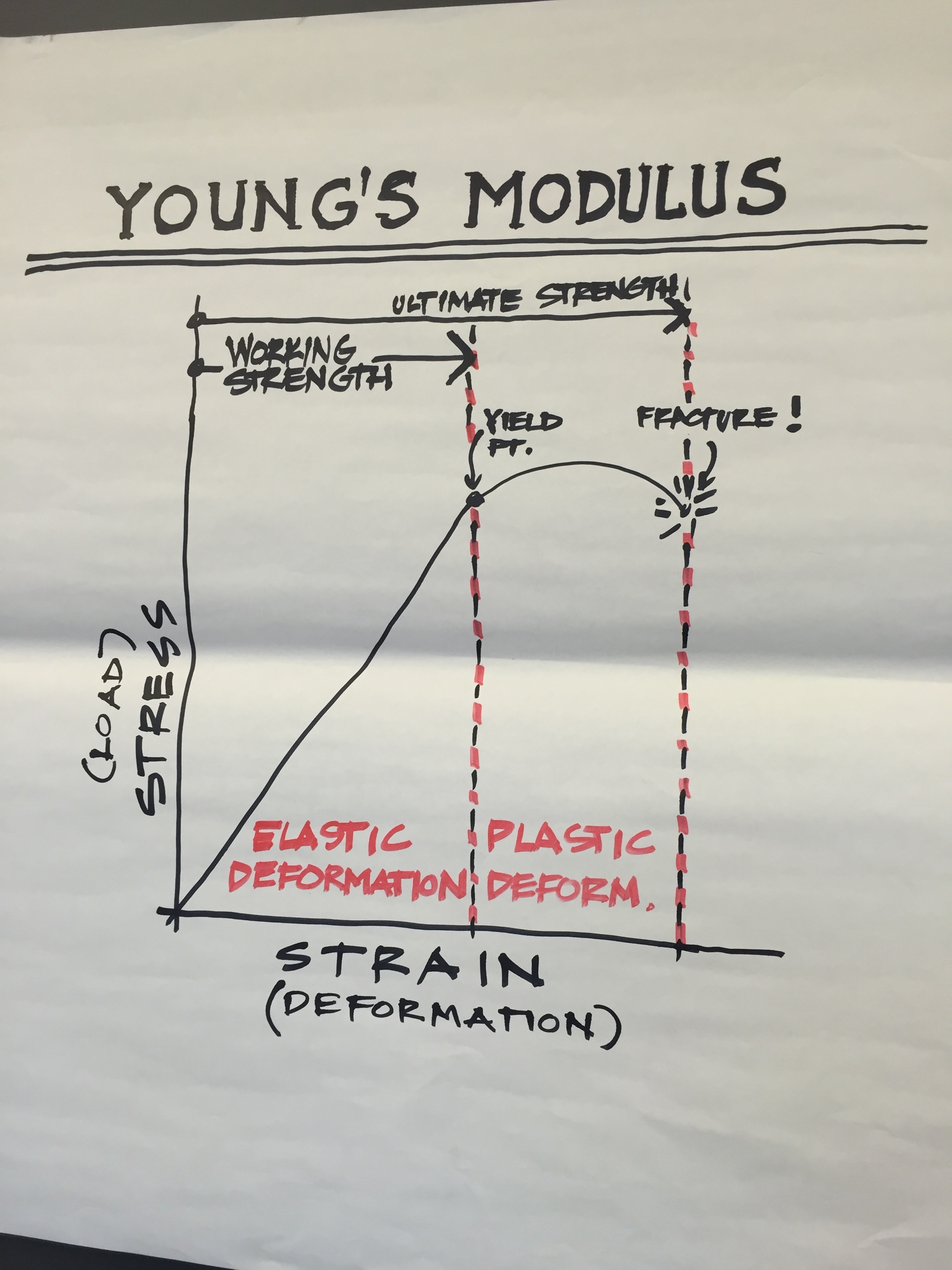

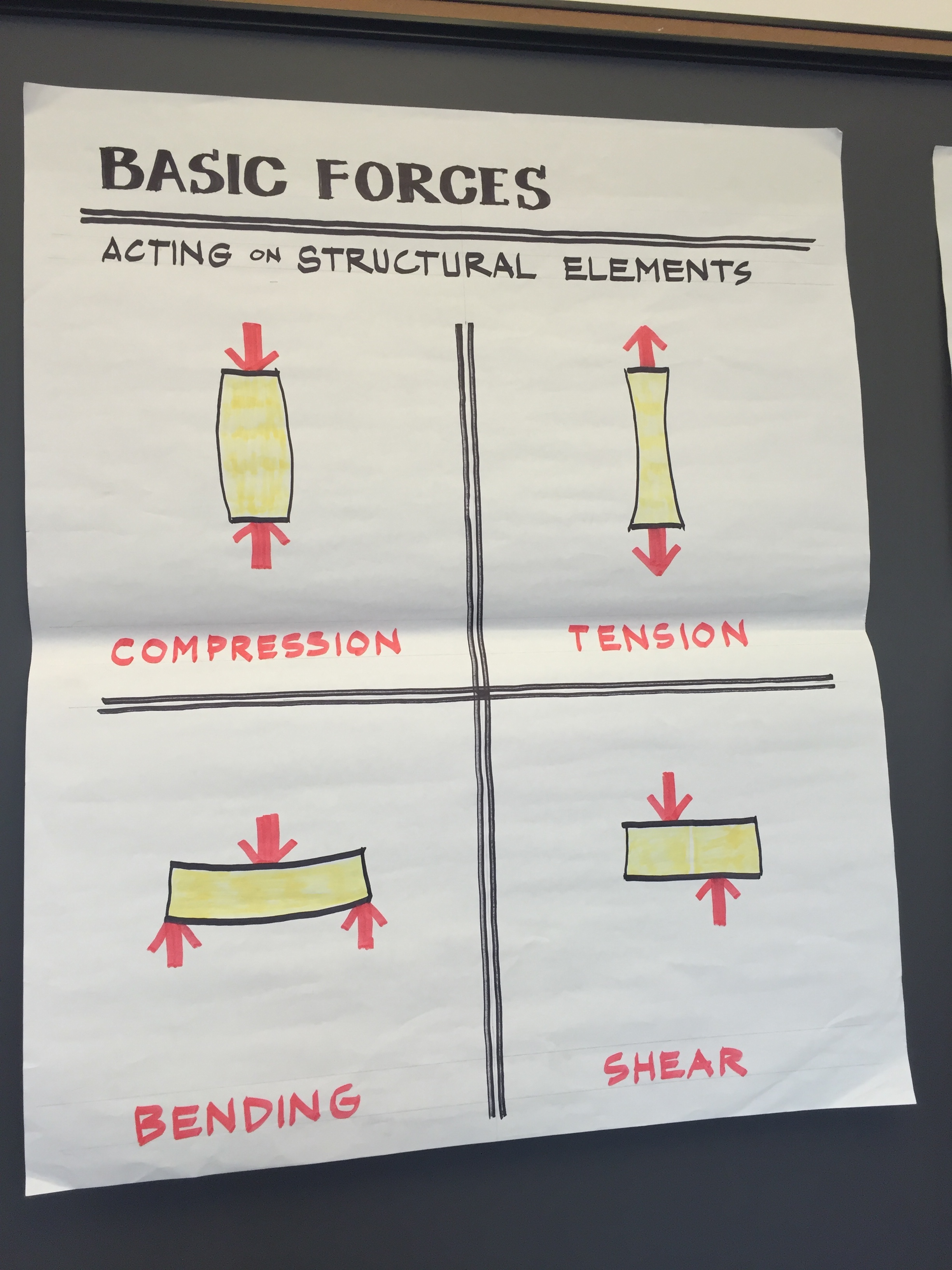

Regarding bending: It is a combination of compression and tension

Goal: to tighten the spokes uniformly so the rim is concentric to the hub, and the hub is in the middle

The spokes are completely incapable of taking any force or compression

The spokes that are closest to the same plane of pressure are doing majority of the work, and as you move further, they are doing less work. They aren’t carrying any force of gravity, only keeping the wheel in line

Acceleration: the spokes that are in tension are doing the work

Tap the spokes to test tightness