Bill Becker:

- Architect. Currently, in retirement, restoring motorcycles.

- He read a book about how kids draw wheels. It was just lines. It looked stupid, yet that is how wheels were previously made/looked.

- Mass – how the matter in things reacts to forces. Particularly, the mass in other objects.

- Inertia – how the mass reacts to moving (stopping and going).

- Scooter/bike have less mass in the wheel.

- Motorcycles are performance-based vehicles. Many times, they are for sports too. You want them to be as light as possible, strong, and overcome inertia quite easily.

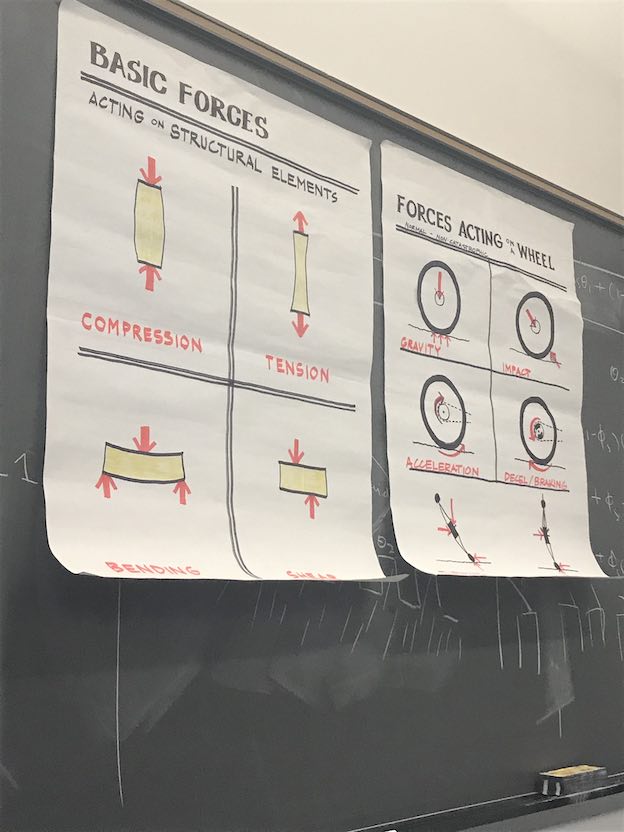

- The forces that act on a wheel:

- Gravity (weight), velocity (magnitude of speed), orientation (the direction you’re going towards)

- Vectors (a simple way of saying the direction of force):

- Helps you analyze how the force is moving in that system.

- Vectors (a simple way of saying the direction of force):

- Gravity (weight), velocity (magnitude of speed), orientation (the direction you’re going towards)

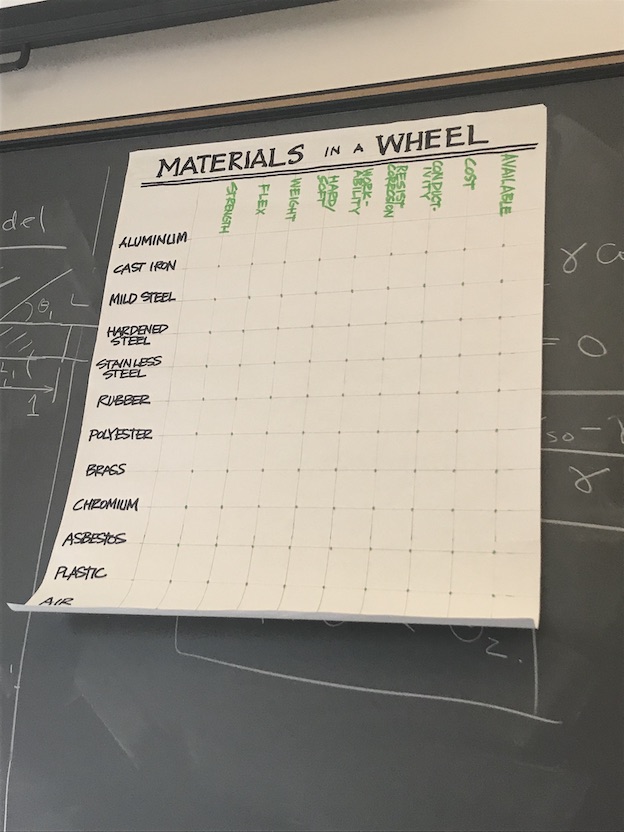

- Materials:

- Most motorcycles have aluminum hubs or rims.

- Cast iron in hubs.

- Mild steel you can see in stamping, and the rim is stamped out of mild steel.

- Hardened steel in ball bearings.

- Stainless steel in spokes.

- Rubber in a tire.

- Polyester in a tube.

- Brass in the nipple of air in the tube.

- Chromium in paint so it does not rust.

- Asbestos in brakes (not today).

- Plastic in the retainer of bearing.

- Air

- Pick materials based on what you want the material to do, but it has to be designed to withstand whatever loads they are subjected towards.

- Dead load: simply the weight of the object itself. Being subjected to the forces of gravity.

- Live load: the driver, passenger, luggage, etc.

- Static load: the weight not in motion, just sitting there.

- Dynamic load: loads in motion. Example: Hammer’s head.

- The geometry of the wheel:

- Compressive force: mass causes something to be squeezed.

- Tension: opposite of compressive.

- Bending: only compression and tension.

- Sheer: separating the atomic structure within the material causing it to rip.

- Autonomic structure of the material is holding the neutrality. There is a neutral axis down the middle.

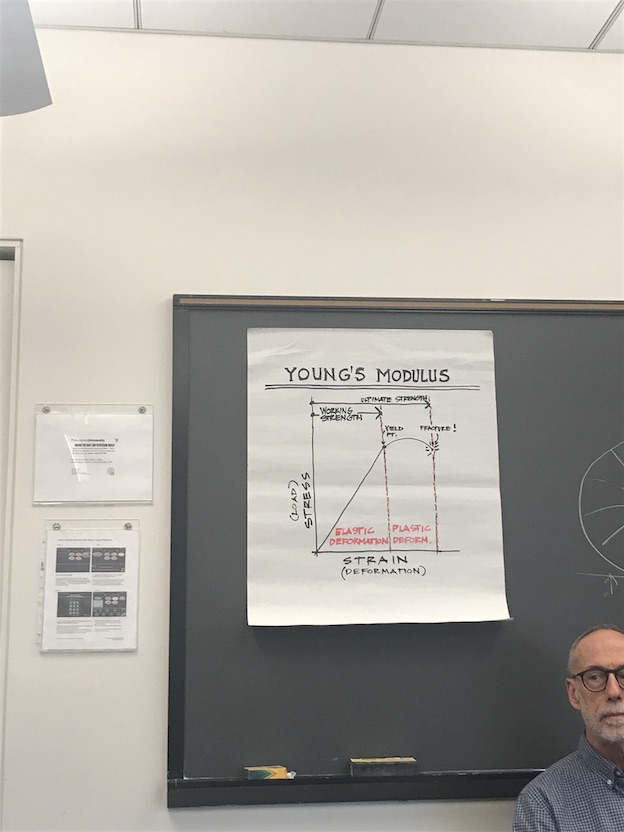

- Young Modulus was a physician. He wanted to know why materials behaved the way they do. He discovered a relationship between force you put on a material (stress load) and how it reacts. Strain is the reaction to stress. When you put the material under stress it will react in strain through deformation. It gets to the point where it approaches its yield point, goes through a deformation, then fails. Example: rubber band.

- The rotor forces action on a wheel.

- Forces are being applied to the hub (in tension) and are being transmitted to the wheel, then to the rim (in compression) through the spokes. Spokes can’t transmit a force, because it is a triangle, it is able to pull the rim around. Therefore, we talk about the forces flowing through the spokes. Spokes are in tension. The more load you put on it the straighter it gets. Effective by the virtue of it its number. Contribute to the strength of the wheel. (Now, they are casting.)

- Dynamic loads from turning.

- When you start to load sideways. What do you think is happening? Who is doing the work?

- Compression on one-side and tension on the other.

- When you start to load sideways. What do you think is happening? Who is doing the work?

- Work the spoke is capable of doing.

- 8-inch diameter for 6900 psi – holds up about 860 pounds by itself.