Lab Recap

Bottom End: Put engine back into the frame. There were scratches on the surface, which is a problem with the sealing. It is a problem because of air leaking out or gas leaking in. It was sent down to the shop.

Detailing: Gas tank and headlight back on the frame of motorcycle. Still need to put in the carburetor.

Top End: Cut the valves. The angles were cut at 30, 45, and 120 degrees. Glen put a drill on the shaft and spun it, instead of using the suction cut device. Used a three angle cut. When the valve sits in the seat, it hits the middle of the seat. Used bluing compound to find the surfaces the valve touches the valve seat. Seats were hardened, cast iron. Seats and valve have to be gas tight.

Frame: Painted more coat on the fork tubes. Will start working on the swing arm.

Electrical: Redoing the clutch cable on the red bike and modeling it after the green bike. The clutch cable was too long and so wasn’t kickstarting efficiently. When routing the cable, want to avoid sharp kinks because this leads to non-smooth draw and release.

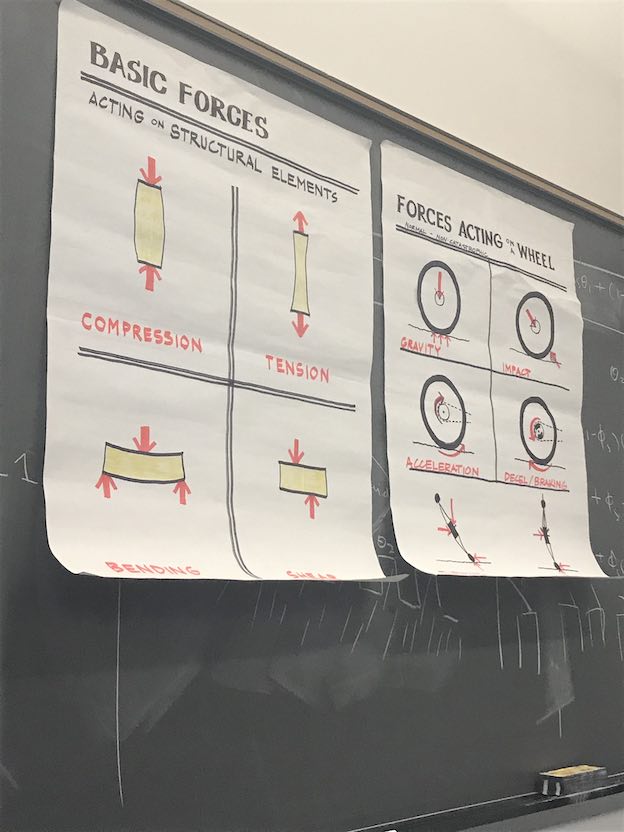

Wheels: Working on lacing up the wheels and found out the phalanges were matched with the wrong hub. Looked in the past at the rim to figure out the large phalange and the small phalange. Possible that the previous decision as wrong. Spokes were going all the way through the nipple, and professor was concerned that that would cause a problem on the nipple/nut. The shaft diameter was not 0.134, nut smaller: 0.120. John thinks these are rolled threads.

Book Discussion

Introduction and Chapter 1

Discussion Leader: Simon

Intro Brief Summary: Hiding the works of machines that we use, decline in using tools makes us have a more passive relationship to material things. Will argue that working and fixing things with your hands is meaningful because it gives us agency. Not just the romantic aspect, but the utilitarian aspect. Agency is doing it for yourself, and confidence is knowing what you’re doing.

Intro Tech References: Some cars are designed to not have a dipstick, which reflects a lack of interest in working mechanically on your own car.

Ch1 Summary of Part 1: “Psychic satisfaction” Talks about experience as electrician starting young. Learned the value of doing things well, even if no one is going to see it.

Ch1 Summary of Part 2: In a period of time of the assembly line, the concept of manual labor started to shift to take independence and thinking out of it in exchange for efficiency. More effort back then to include vocational training in school. Makes distinction between craft and trade. Some type of manual jobs (plumber, carpenter) are more secure because it’s not efficient to have machines do them.

Discussion: Why have people started looking down upon blue-collar working (eg plumber)? Because of the idea that education pushes society forward, and that plumbers aren’t going to push society forward as well. Also the idea that we don’t really realize that we need plumbers until our plumbing breaks. Are there really any jobs that can’t be replaced by automation and technology? Henry Ford dumbed down the trade of manufacturing. He increased inefficiency by increasing specialization. They have been moving back to increasing trade-based positions in companies like Barclays. In America we value intellectual stimulus in 4 year college, as opposed to a 2 year trade school. Another element of the book is to see the physical fruits of your work. The carpenter gets immediate feedback on whether his building is level. Problem solving versus problem finding: Psets are problem solving, whereas fixing a washing machine is diagnostically finding a problem. He says this is more high-level thinking.

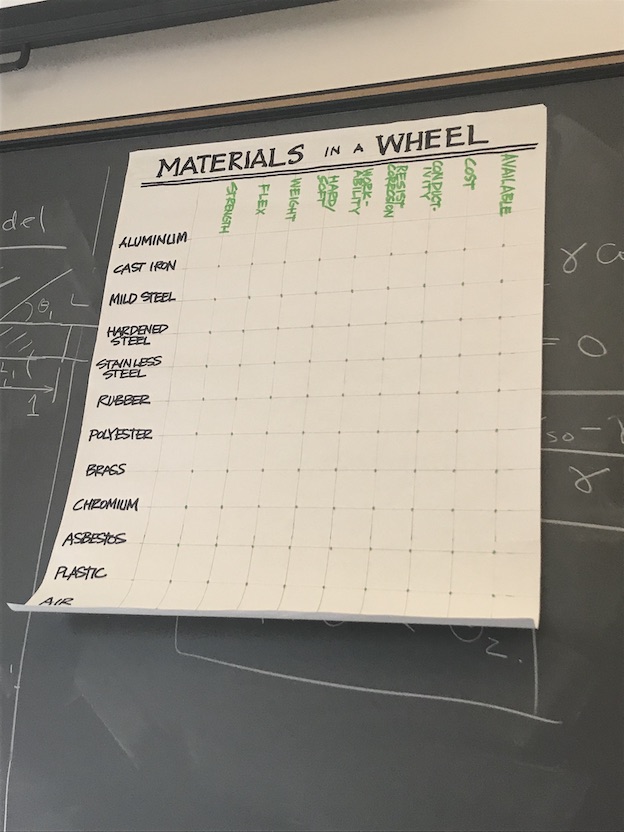

Looking at 3-d modeling.

Computerized design, computerized engineering manufacturing. Safety factor of 2 means you’re in 2 degrees of failing. Thursday will bring in a 3d printer, to print out 3 axis mill.