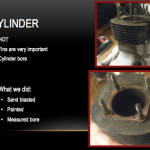

– Hottest part of the engine

– Fins are very important for air cooling because heat is released through the fins

– Cylinder bore guides piston within the cylinder and helps seal combustion chamber

– We did not really have to bore our cylinder because it was in pretty good shape.

We were able to use standard piston because the cylinder had very little wear. We had 3 one thousands of an inch of clearance between the piston and the cylinder, which is well within the manual specifications. If we were outside the specifications, we would have had to use a larger piston. Bike revs so low at 6000 rpm because of the long distance that the piston needs to travel to TDC. For comparison, a 2015 Kawasaki ninja revs at 12000 rpm with a bore of 62 mm and stroke of 49mm. Our piston was new old stock and was in the bag from 1957 with original oil on it. We had to clean that off and attach the piston head to the crankshaft by pushing the wrist pin through the head of the crankshaft. Once we did that, we had to put the circlips in to hold the wrist pin in place and then put piston rings on. Now, we had to lower the cylinder onto the piston, which was slightly difficult to get it over the piston rings. I had to hold the cylinder and push it down while John pinched in the piston rings. However, this is a good problem to have because if the cylinder had just slid onto the piston, we would have a lot of space on the outside of the piston and lose compression.

– There are two valves in our engine head, the intake and the exhaust valves.

These valves are controlled by two springs which in our case were connected and coiled opposite directions. This makes the spring extremely tight and hard to compress and then these springs are controlled by the rocker valves.

Fuel + Air= motion and that is exactly what the carburetor does. It injects air into the fuel, allowing the engine to burn fuel more efficiently. Carburetors vary by design and complexity but here is a simple explanation of its inner workings. Air flows into the carburetor through the carb’s air intake. Then, the air is forced through a narrow kink called a venturi , which causes its air pressure to drop. This creates a suction on the fuel pipe and draws fuel into the carb. The throttle is a valve which opens and closes the pipe, enhancing or restricting the amount of fuel entering the carb. Then, the mixture of air and fuel enters the cylinders. As the fuel level in the chamber falls, the float falls and opens the valve at the top. The more the valve opens, the more fuel flows in. The fuel flow is once again either restricted or enhanced by the float. This is important because the engine needs different fuel mixtures depending on what it is doing. If the engine is trying to start, it needs more gas and less air, which is accomplished using the choke. If the engine is idling or running flat out at top speed it will need a different fuel-air mixture so it can perform optimally or not stall. This is the function of the carb.

Now, the carburetor on our bike was relatively complete. We took it apart, took inventory of all the parts, then we found the missing parts on other carbs that we had leftover from previous years. Once we had all the parts we re assembled the carb and tested it on the orange bike to ensure that it worked.