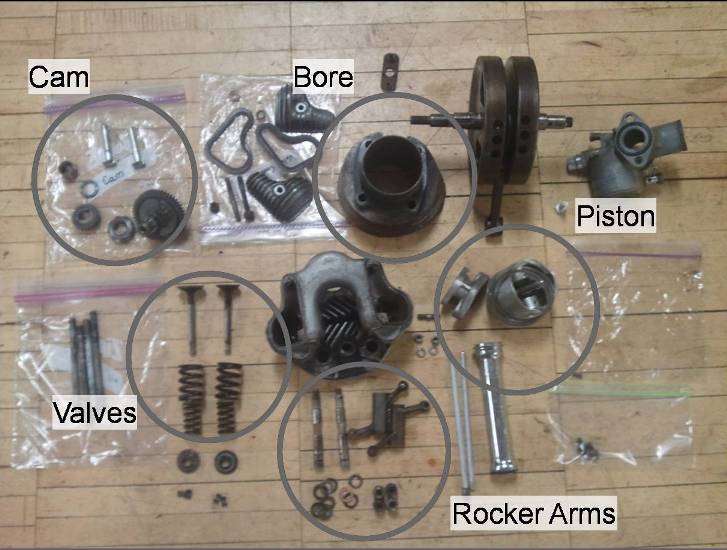

- Cylinder

- Crankshaft

- Piston and rings

- Cam

- Lifters

- Push-rod assembly.

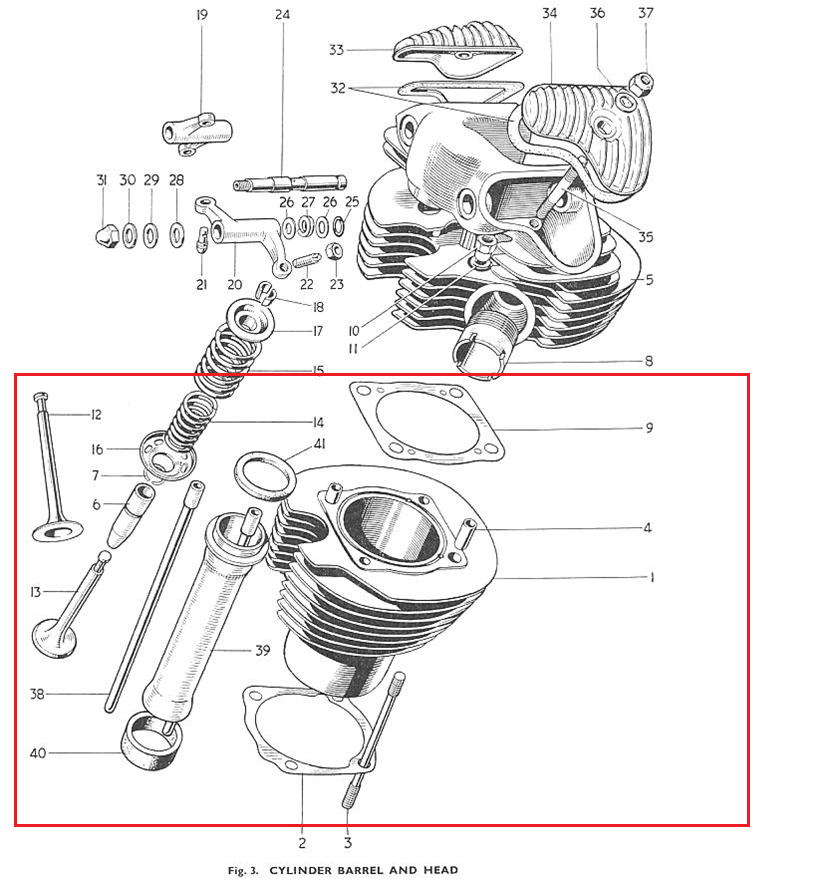

The head bolts onto the top of the cylinder, and the two pushrods connect the motion of the cam to the movement of the valves.

Exploded Diagram of Cylinder and Pushrod Assembly

The Beginning of the Restoration

The cylinder needed to be rebored

It was wrong from the previous boring job, bored off center and tapered as well. We decided to make it 0.060 inches over its original diameter, and ordered a new piston to fit that new size. The bore of a cylinder is a measure of its inside diameter. We bored the cylinder on the lathe, bolting it onto a custom jig using the four holes for the head bolts. The idea here is to take only a few thousandths off at a time, and advance the cutter slowly to create a uniform surface.

The desired result is to have the bore diameter just slightly more than the piston diameter, within a few thousandths, allowing the piston rings to squeeze out against the inside of the cylinder and form a seal. Once the correct bore diameter is established, the cylinder wall has to be honed, which removes scratches and grooves made from the cutting tool. The honing tool is also used to create tiny vertical grooves in the cylinder wall, allowing oil to move vertically in the cylinder.

If the grooves from the boring were left in oil would only move in a spiral fashion, and the cylinder would be ineffectively lubricated. The piston rings have gaps in them for two reasons.

- The first is to allow room for expansion, so the rings can expand when they heat up and not bend

- The second is to allow oil to move throughout the cylinder. The tiny gap allows a miniscule amount of oil through to lubricate the walls. Too large of a gap will decrease compression, while too small a gap can cause the rings to bend or the engine to overheat due to lack of lubrication.

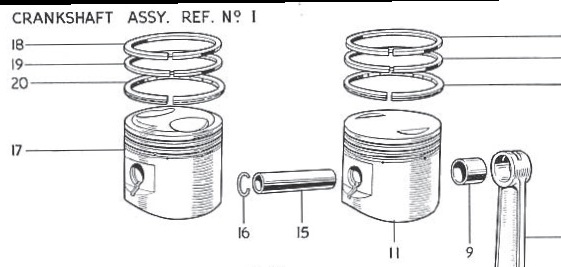

Piston and Rings

There are three rings on most pistons. The main functions of these rings are –

- To seal the combustion chamber

- Regulate oil inside the cylinder

- Transfer heat from the piston to the cylinder to the cooling fins on the outside of the cylinder.

The two rings closer to the top of the piston are intended to seal against compression loss, while the bottom ring controls the movement of oil inside the cylinder. This one allows oil to move around the outside of the ring, leaving a lubricating layer of oil on the walls of the cylinder.

The piston rings have gaps in them for two reasons.

- The first is to allow room for expansion, so the rings can expand when they heat up and not bend

- The second is to allow oil to move throughout the cylinder.

The tiny gap allows a miniscule amount of oil through to lubricate the walls. Too large of a gap will decrease compression, while too small a gap can cause the rings to bend or the engine to overheat due to lack of lubrication. The piston is domed, which decreases the size of the combustion chamber, increasing what is called the “compression ratio” of the engine. This number is the ratio of the pressure in the cylinder above the piston at the top of its travel (smallest volume) divided by the pressure when the piston is at the bottom of its travel (largest volume).

The piston we have creates a higher compression ratio than the stock piston. A higher compression engine is a higher performance engine, because it has a higher thermal efficiency. The air-fuel mixture is more concentrated, and the adiabatic heat of compression increases the temperature of the mixture. These two factors result in a better fuel-air mixture, which increases the power of the engine.