Team – Adam, William, Robert, John

A clutch is a device used in machines to transmit power from the engine to the transmission. It can be engaged to allow the engine and transmission to spin at the same speed or disengaged to allow them to spin at different speeds (thus allowing the rider to shift gears).

Why do we need a clutch?

The clutch allows for a smoother shift from gear to gear. Without a clutch the transmission would wear down over time. Without a clutch, the only way to stop the wheels from spinning would be to turn off the engine (because otherwise whenever the engine spins the wheels would too).

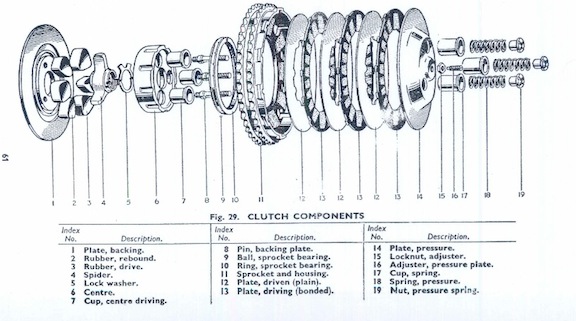

Backing Plate

Composed of backing plate, rebound rubber, drive rubber, spider, lock washer, centre, centre driving cup, backing plate pin, sprocket bearing ball, sprocket bearing ring

Sprocket and Housing

Notice that is has double sprockets.

Driven and Driving Plates

Driven plates have lugs on the inside to engage with the engine and are made of steel. Driving plates have lugs on the outside to engage with the transmission and have pads made of cork.

Pressure Plate

Spring Cups, Pressure Springs, and Pressure Spring Nuts

Sprocket and Primary Chain

Why does it have a double chain?

The double chain was an innovation because the single chain on previous models caused the sprockets to wear down and break, while the double chain is more durable.

How the Clutch Works

When the clutch is engaged, the driven and driving plates are pressed together by the pressure plate and springs and spin at the same speed. When the clutch lever is pulled, the clutch operating rod pushes up on the pressure plate, disengaging the clutch and allowing the engine and transmission to spin at different speeds, thus allowing the rider to shift gears.

Having multiple plates increases the friction, thus reducing the slippage. The greater the friction, the greater the torque that the clutch can handle without slipping.

Length of the spring = 1.53in. = .1275ft.

Length of the spring after 20 lbs. of force applied = 1.324in. = .1103ft.

Number of moving surfaces in contact = 7

Coefficient of friction of cork on steel = 0.8

Diameter of the clutch = 5.33in. = .444ft.

Given:

The clutch slips at 50 ftlbs. of torque

Calculations:

F = kx (force on the springs)

F = uN (force of friction)

T = rF (torque)

k = F/x

k = (20lbs.)/[(1.53in.-1.32in.)(1ft./12in.)]

k = (20lbs.)/[(.21in.)(1ft./12in.)]

k = 1,143lbs./ft.

T = rF = 50 ftlbs. = .22F

F = (50ftlbs.)/(.22ft.)

F = 227.27lbs.

F = uN = 227.27lbs.

F = 7uN

F = (7)(0.8)N

227.27lbs. = 5.6N

N = 40.6 lbs.

Force applied by each spring = N/3 = 13.53 lbs.

From there, we can calculate the amount of initial compression required when each spring is screwed in to generate this amount of force so that the clutch will slip at 50ftlbs. of torque.

F = kx

13.53lbs. = (1143lbs./ft.)(x)

x = .0118ft.(12in./1ft.)

x = .142in.

So given torque, we were able to find the force applied by the springs and the distance we need to compress the springs initially to generate this force. On the other hand, if we assume a certain amount of compression in the springs, we could also find any torque.