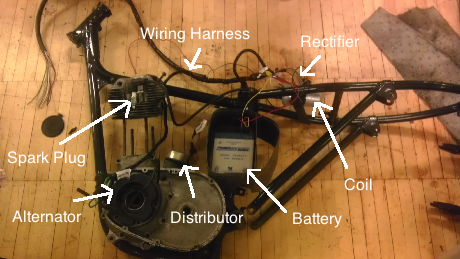

Alternator

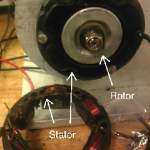

Rotor and Stator

The alternator generates AC current to charge the battery and power the bike’s electrical units. It consists of two parts: the rotor and the stator. Connected to the engine, the rotor is a six pole magnet that is driven by the crankshaft in a one-to-one ratio. The stator is a part around the rotor that has six alternating coil windings connected in series. As the rotor spins with the rest of the engine parts, the spinning magnet generates electrical current in the coils through electromagnetic induction.

Battery

The battery runs on DC current and provides electricity to power the bike. It has three cells, each of which has 2 V, for a total of 6 V.

Rectifier

Since the alternator generates AC current to charge the battery and the battery runs on DC current, the rectifier is needed to convert the AC current into DC current. It consists of four semiconductor diodes, which are one way valves for electrical current.

Ignition Coil

The ignition coil is a step-up transformer made of a primary and a secondary coil wrapped around themselves. The secondary coil has 100 times more turns than the primary coil. This means whatever voltage that enters the primary coil is multiplied by 100 times in the secondary coil for external uses.

Spark Plug

The spark plug is what ignites the air-fuel mixture in the engine to start the motorcycle. To do this, the spark plug requires a very high voltage (provided by the coil) to force the electrical current to jump across a gap. It also has a porcelain insulator to ensure that the spark happens at the tip.

Distributor

The distributor is a very important part as it contains the cam, the condenser, and the contact points. As the distributor cam rotates with the engine, the points are pushed apart at specific timings to break the electrical circuit, which eventually causes the spark in the spark plug. The condenser stores current and discharges it as part of the electrical circuit. We measured the condenser to be 265.7 nF.

Wiring Harness

The wiring harness connects all the wires and allows electricity to flow throughout the bike’s electrical units. We were able to use a pre-made wiring harness as a template. We still had to make extra wires, using soldering techniques to connect separate wire tips. We also had to make sure there was electrical contact on the frame to ensure proper grounding of the entire electrical circuit. This consisted of scraping paint away from from the frame so that there is metal to metal contact.