MONDAY

- Introductions, students shared the most memorable thing from Professor Arnold’s previous presentation

Guest speaker: Bill Becker (architect, economist, engineer, motorcyclist) on Motorcycle Wheels

- Why do motorcycles fail? Under-engineered, material failure. Reverse engineering can make materials stronger/faster

- Focus: motorcycle wheel

- History of wheel

- First wheel: something round. Stone, wood.

- Wooden rim, spokes: not used on motorcycles

- 1895 Germany: first motorcycle, basically a bicycle

- Front wheel attached to hub, center point: axel, no brake

- Rear wheel solid

- Modern motorcycles: cast wheels > spoke wheels because labor is cheaper

- Triumph Tiger Cub wheel: spokes, larger on one side for brake

- Topics: thinking as designers and engineers, material science, geometry, engineering and stress tests

- Terms

- Mass: how much matter is in something, gives things weight, intertia and momentum (energy needed to start/stop mass)

- Motorcycle wheel has evolved to combat weight

- Forces: acting on mass. Torque, etc.

- Mass: how much matter is in something, gives things weight, intertia and momentum (energy needed to start/stop mass)

-

- Vectors: direction and amount of force in object

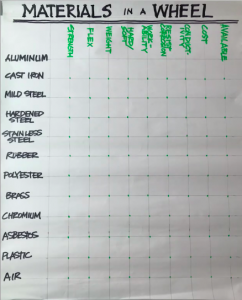

- Materials in a wheel: what they are and their properties

-

- Strong steel, lightweight aluminum

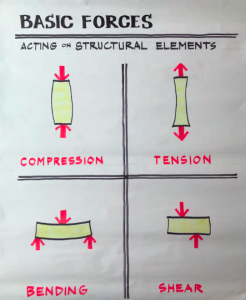

- What forces do to structure diagram

- Materials can resist one force easily and buckle under another force

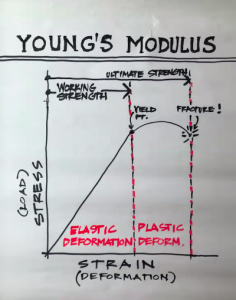

- Young’s Modulus: relationship between stress and strain

-

- Stress: force, strain: reaction of material to force

- Steel takes high stress, has high strain with little deformation

- There’s a limit to elastic deformation (snaps back to original form), yield point to plastic deformation (not failure but doesn’t come back to original form) until point of fracture.

- Rubber band example

- Any material is a matrix of atoms

- Steel plastic deformation: a wheel

- Littman – Airplanes: pressure + altitude

- Jon – Also why things fail: temperature. Bending a rubber band quickly = high temperature at the molecular level, so bending a rubber band slowly saves its elasticity more than bending it quickly

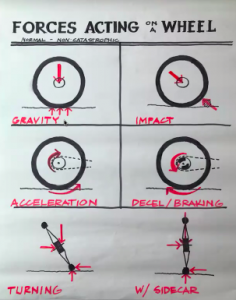

- Forces acting on a wheel diagram

-

- Gravity caused by: load

- Impact caused by: mass resisted by object

- Acceleration: motor’s power torque goes to transmission to chain to sprocket to hub and torqueing transmitted from hub to rim through spokes

- Deceleration: similar to accel: acting

- Most motorcycles: 36 spokes, British motorcycles 40 spokes

- Spokes work in tension, they’re not securely fashioned to the rim

- When you’re accelerating hub, only half of the spokes are contributing

- When they work in compression and spokes are too long, they’ll poke your inner tube

- Spokes don’t go straight to center of wheel because there’s torque on hub and on where tire meets the road. Better when some are off set (so spokes can lengthen/shorten under strain)

- Rim tension hub compression: spokes are in tension

- Web of 40 objects, all of them in tension. Pre-stressed structure

- Unique geometry of wheel: triangular sub structures

- Spokes positioned forward and backward, left and right, creating triangles

- Spokes in wheels also allow air movement: wheels not tipped over by wind

-

- Bike wheel: brake applied on rim. Motorcycle: braking at hub, so spokes have to transfer work to rim

- Spokes aren’t universal; they’re made for specific wheel on specific type of specific motorcycle

- Inside and outside spokes

- Tap the spokes: each give the same musical note, because every one is in harmony

- Jon: all Triumph and British motorcycle repair videos are available to stream on Amazon Prime!

- Wednesday reading: chapters 5 and 6

WEDNESDAY

Show and Tell!

- Littman: wheel with spokes (20 spokes leading, 20 trailing)

- When spokes are in tension, hub rotates -> rim rotates

- Rupert: “Meg the 2001 MGF”

-

- at first: didn’t start, very dirty

-

- repair: trickle charge the battery

-

- careless design in the “boot”, battery doesn’t fit in the bay so made a makeshift part

- clean the engine, clean and check the fuel system (fuel injectors)

- alternator belt was fixed

- it ran!

-

- It’s a negative ground battery (negative side connected to the frame)

- Jake: Bike

-

- It’s a 2-stroke engine, so there’s no top end

- Power stroke every two strokes, so if there’s a compression problem, it’s bad

- Problems with fuel being pumped in

- Spark plug worked

- Got it running

- Recently got a chain breaker

- Master link: the one section of the chain that can be manually detached to fix the chain

- 1:20 ratio of oil to fuel

- Shearing issue

- 110 cc engine

- 2 stroke: a little less than 2x power of 4 stroke

- No battery, bump start it, shift and the clutch starts it

- Mountain bike transformed with motorized kit

- It’s a 2-stroke engine, so there’s no top end

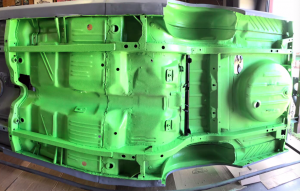

- Taylor: “Duster” car

- Before: red car sitting in a field

-

- After: green car, doors and fenders not on it right now

-

- 3-18 specs of motor

-

- Not original motor; it’s a racing engine

- ’67 Shelby in the shop

-

- Better heating/AC: more efficient, less space

- Unibody car: doesn’t have a frame

-

- Fuel injection: Holley Sniper

- Gas mileage on truck: 18mpg

- Macey: Land Rover

-

- Defender model, 110 inch wheel base

- Leaks, hard to drive

- Kate: 1962 Buick Special, recently fixed up

- Fun fact: gas is currently $1

- Jon: motorcycle

- Anna: car

Reading: Chapters 5 and 6

- Motorcycle references

- Resistance to the flow: friction

- Voltage and current

- If you hold a bearing in the center and put compressed air into it, it will spin at high speeds and explode

- Self-absorption: digging too deeply into motorcycle repair (going out of your way to find problems to fix) vs. value of work

- Better safe than sorry: fix it anyway

- Caring too much vs Pirsig’s “idiot” not caring enough. There’s a middle ground

- Silicon Valley work benefits: Google water, swimming pools, laundry service, college education at work

- Attracting workers, keeping them there, keeping them at work longer to increase work hours/productivity

- Teamwork vs individual work as a member of the crew

- Happiness at work: a good job “satisfies the desire to know”

- Can you find fulfillment in having knowledge but not applying it?

For next week: finish Shop Class as Soulcraft