Students:

Isa Gomes ’25 Katie Bender ’25

Backround:

Project Nibbler started in 2019 led by the R&D team at Avenues São Paulo, and Isabella was one of the

founding members. Nibbler’s goal is to bring recycling to the home. The machine combines 3D printing

and grinding technology to fabricate objects out of trash. The fabrication process within the machine

happens through two steps:

1. Trash is ground up into small particles;

2. A new object is 3D printed with particles of trash using UV resin is used as a binding agent.

A US Patent (Application No.: 17/316,887) for the project was filled on May 11, 2021, and the team is

currently working on further developing a prototype for the machine.

Concept Prototype in São Paulo and Proof of Concept Print (Not done by Team Princeton this year).

Nibbler prototyping is currently divided into two projects: grinder and 3D printing technology. The current prototype for the grinder uses an open-source shredder design combined with a coffee grinder to reduce trash to particles of approximately 3mm size (shown in Figures 1 and 2). The current design for the forming chamber uses an Ender-5 Pro 3D printer as a basis. Currently, we are using a dual extrusion method to extrude particles of trash followed by the extrusion of resin. Both extruders were 3D printed and hacked into the printing head (shown in Figures 3 and 4).

Currently, Team Princeton is working with the Community Project Studios class to develop an identical prototype to the São Paulo, New York, Silicon Valley, and Texas teams. In the upcoming semester, we will try to improve the printer, and accomplish the following goals:

- Make the product more marketable. We want to make it look more like a consumer product and less like a prototype to make it easier to publicize and easier for people to understand.

- Experiment with printing to make it more precise. This includes fine-tuning the resin drip and figuring out an effective way to distribute the nibbles.

- Make the curing process more seamless. This could possibly be done by adding UV LED strips, but we would have to be certain that surrounding the chamber with UV light would not harden the resin in the syringe.

- Make the resin and nibbles systems easier to refill or create reservoirs

Work with the other Nibbler teams to integrate the grinding and printing mechanism

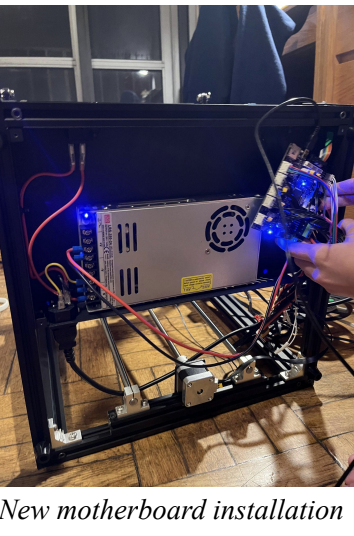

This semester, Team Princeton was able to 3D print and assemble the resin extruder, assemble the base Creality Ender 5 printer, hack the printer and install new firmware, rewire the printer with a new motherboard, and install a new stepper motor to enable the dual extrusion. We used a lot of hand tools to assemble the printer, and we used a soldering iron to switch the polarity of the Nibble Extruder motor. At the inception of the project, in order to print something, the G-code had to be written manually. The new firmware on the printer allows us to execute prints with both motors more easily.

So far, we have not used any of our Princeton budgets, as Avenues funded the initial printer setup. We plan to use the CPS budget to invest in UV LED strips, nice materials for the casing, and off-the-shelf/ more commercialized parts for the extruder so it does not have to be 3D printed. We are unsure of the materials, as we have focused most of our energy on making the printer function. We will ideally perform test prints before we leave for the summer, and begin optimizing the system when we come back next fall.