Students:

Brandon Spellman ’24

BSE – Computer Science

Background

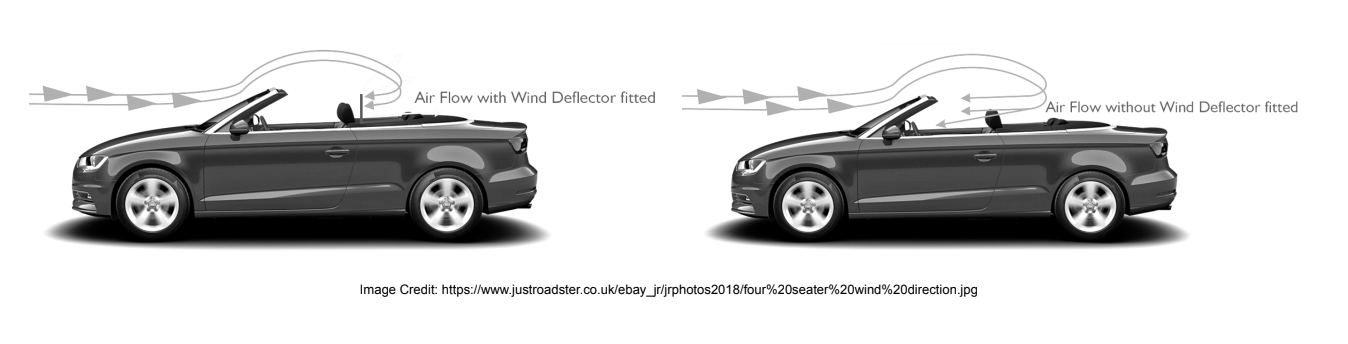

The project I created was a wind deflector for a convertible. It is a clear sheet of polycrylic which stops wind from blowing back into the driver and passenger seats (see the diagram below). This product significantly decreased the noise when driving, and also increases the effectiveness of AC and heat since it doesn’t get blown right out of the car.

Progress Pictures

Carefully measured out the fitment of the wind deflector, and traced out the final template in red onto the polycrylic sheet. I cut out the outline with a combination of a circular saw for the straight lines and a jigsaw for the curves.

Made several jigs and sample tests in order to bend the polycrylic sheet. The method I eventually settled on was 1) removing the protective sheathing from both sides of the plastic, 2) clamp scrap wood blocks to shield the rest of the plastic and make sure the heat was localized on the bend, 3) use a heat gun on each side of the plastic to evenly heat the bend, 4) use the wood blocking to bend the softened plastic sheet, 5) make fine adjustments with the heat guns so the bends match the profile of my sample testing bends.

I then attached a string of waterproof LED lights to the bottom of the wind blocker and plugged the USB into the center console. It’s an RGB LED strip, so I can change the colors with a remote that is also in the center console.