Students

Andre Griffin

COS, 2020

Ramzi Haddad

HIS, 2020

Alex Deters

CLA, 2020

Project Description

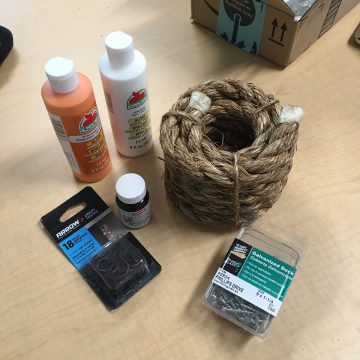

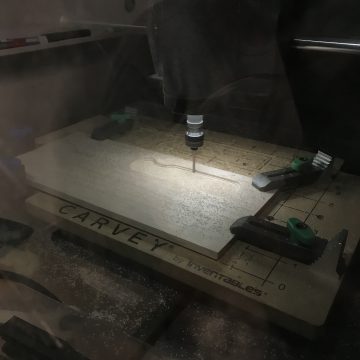

This project began in the Fall Semester as we created knife prototypes made entirely out of wood. We tested out a variety of handle set-ups, blade shapes and orientations, and locking mechanisms. After going through this trial phase of our project, we settled on our current handle and blade shape, as well as our locking mechanism of choice. Using the Fall semester as time for an experimentation process, our group settled on the liner lock mechanism because we felt it was the safest of the available locks, and it would adapt the most readily to a variety of handle and/or knife patterns. Furthermore, we felt that we could more easily produce the liner lock than other mechanisms given our material and production restrictions. While our first semester knives were wooden, their production gave us opportunities to test the optimal locations on the knife handle for the placement of metal pins to fasten not just the sides of the handle together, but also the handle to the knife blade itself. Using these lessons learned from the Fall, this Spring, we constructed an ergonomically designed handle on a Carvey machine from Crosscut Wenge Wood. In addition, we add inlaid wood detailing to the handle. As for the blade, locking mechanism, and fastening devices, we took apart several pocket knives, and then selected the necessary components from each for the construction of our knife. Upon the completion of this project, we produced a fully functioning, durable, and safe pocket knife that can pass a standard battery of tests.

Technical Background

The basis for the scientific and technical background for a pocket knife lies in the mechanics behind the actual cutting of some object. While one imagines the physics behind the simple cutting of an apple or a piece of wood to be relatively self explanatory, there is actually a wealth of experimental findings and scholarly inquiry surrounding said subject. The bulk of the information behind our group’s scientific background came from two studies in particular: The Mechanics of a Shear Cutting Process and Slicing Softly with Shear. From the former experiment and accompanying literature, our group gained several crucial insights to the cutting process. First and foremost, Meissner states the obvious: that knife sharpness, which he claims to be the “radius of its cutting tip” not only affects the level of force required to cut an object, but it also affects the “cut-edge quality” as well (Meissner, 31). Accordingly, a sharper knife requires not only less force to complete its cut, but also leaves the cut object with a better physical result (Meissner, 31). Finally in a study of his experiment’s fracture morphology, Meissner concluded that it was “independent of speed and dependent on preload (ii, 60, 74, 77). From the latter study, our group came to understand that the most efficient way to cut organic materials is done through “slicing action, i.e., dragging the sharp blade over the soft surface without pushing too strongly into it (Reyssat, Tallinen, Le Merrer, and Mahadevan, 244301-1).” They go on to characterize this ‘slicing action’ as a “combination of normal and shearing deformations (Reyssat, Tallinen, Le Merrer, and Mahadevan, 244301-1).” Accordingly, the authors state that for “a giver critical fracture” or successful cut in layman’s terms, “cutting by slicing action requires only a fraction of the force association with pure normal loading (Reyssat, Tallinen, Le Merrer, and Mahadevan, 244301-3)

Meissner, Stephen C. “Mechanics of a Shear Cutting Process.” 1997.

Reyssat, E., et al. “Slicing Softly with Shear.” Physical Review Letters, vol. 109, no. 24, 2012.