Students:

Mitchell Stroebel

John Tracy

Cash Goodhart

Cole Smith

Project Description:

- We are all interested in golf and decided we wanted to make a golf club. At first, we considered a driver or wood but thought this would be too complex and beyond our scope. We settled on a putter since they have relatively simple designs (fewer 3-D curves) and are not hollow (therefore can be created from solid blocks of material).

What we’ve done:

We have experimented with different potential designs in Fusion and printed them with a 3-D printer. A few of the many things we have been considering when iterating through putter designs are

- Weight (the putter must not be too heavy and difficult to swing, but it cannot be too light either and generate no power hitting the ball)

- Size

- Balance (design should have a balanced weight for an easier and smoother swing).

- Feasibility with a CNC machine (must be able to create the design using the CNC machine we have. Therefore we cannot have 3-dimensional curves, only 2-D ones and straight lines).

- Angle of the putter face (how steep to angle the putter to provide for optimal contact)

- Shaft type/placement

- Curves on bottom (curves must be added into the bottom to avoid contact with the ground at the lowest point of the swing).

Photos:

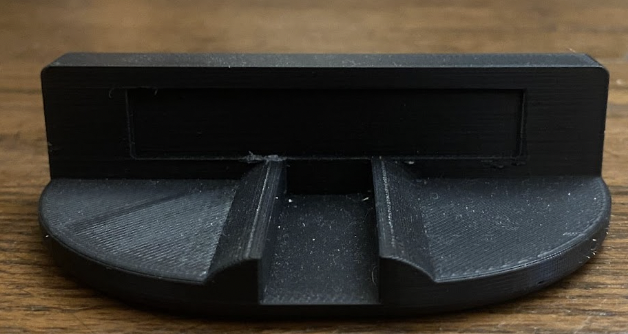

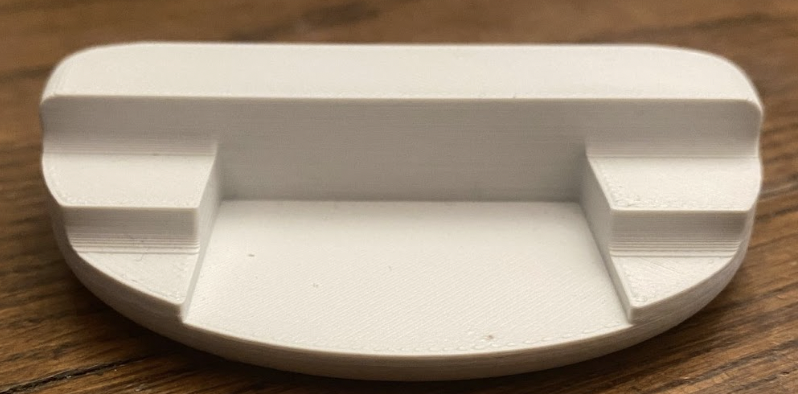

Design 1 (first mallet):

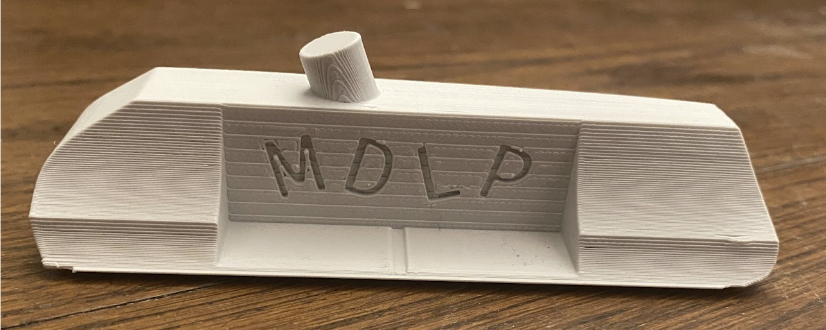

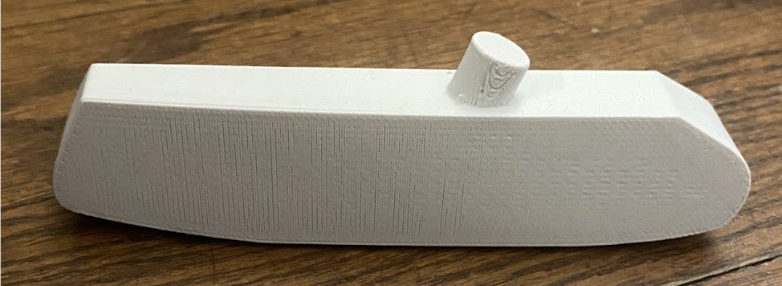

Design 2 (blade):

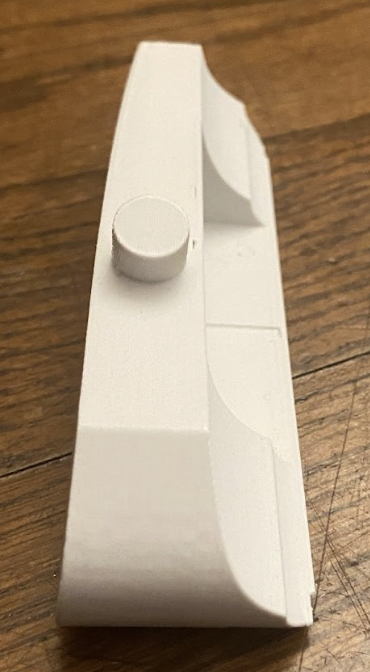

Design 3 (second mallet):

What’s left to do:

Heading into next semester and considering the long-term goal of completing the putter beyond design, we must consider acquiring the materials needed and how to shape that into our final product. The preliminary material we have been leaning towards using for the putter head is Aluminum 6061. The highest quality putters in the industry tend to be made of stainless steel but due to budgetary constraints as well as taking into consideration the milling equipment we have at our disposal Aluminum 6061 made the most sense as it is relatively cheap and also easier to mill than other similar metals.

Once materials are acquired we can begin thinking about how we are going to mill the metal into our club head. This will require a good amount of work in fusion writing the program for the CNC process. In the interest of making sure we are best utilizing our time and resources, we will most likely begin by milling wood to fit our design and then work our way up to metal as we tweak our design to better suit the milling process. After we have our final product of an aluminum putter head, we need to bring the entire product together by ordering a shaft and attaching it to the putter head. Club shafts can be ordered relatively easily, so the heavy lifting here will be deciding how we want to attach the two components. The leading plan at the moment is by drilling a hole into the club head and then fusing the shaft to it with epoxy glue.