Main Goal:

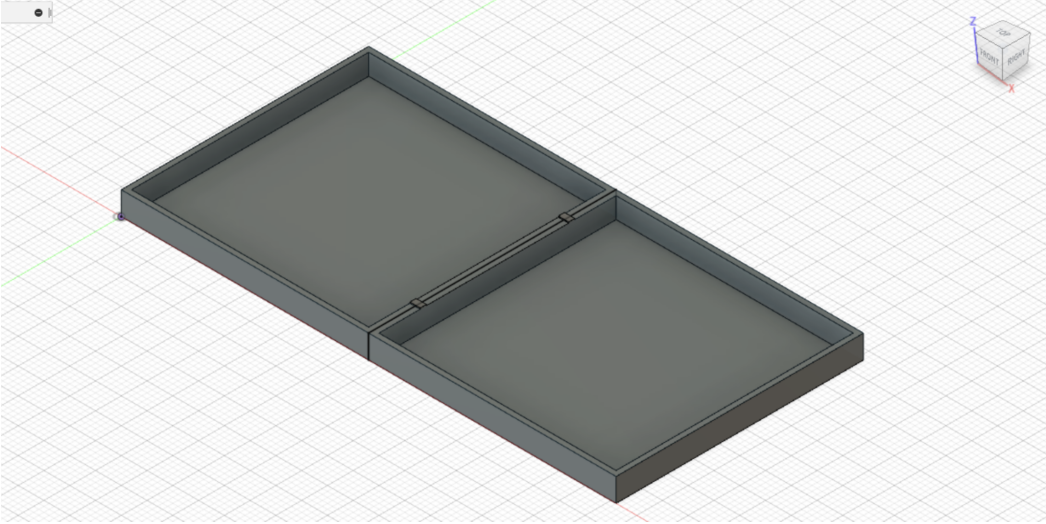

The project is intended to be a portable outdoor game table. Many outdoor games are played on a 8’x4’ plywood table. Most existing tables present two challenges: that the large sheets of plywood are difficult to move and store, and that they tend to warp when exposed to liquids. Our table sought to solve both of these problems by creating a folding mechanism that would support the plywood from the outside, preventing warping, while also allowing the table to be folded in half for easier transportation. Our final design, despite being heavier than most simple plywood tables, is far easier to move because its 4’x4’size allows it to fit in the back of most cars.

Materials Used:

To build the table, we used a table saw to cut the plywood sheet in half, a miter saw to cut the boards to size and an electric screwdriver to drill pilot holes and insert screws. We spent most of our budget on the plywood to ensure we had a high-quality surface on which to play dice games. The plywood is also 1⁄4” thicker than most plywood used for the outdoor game table designs we found online—this decision ensures minimal warping of the table for a smooth surface for years to come.

Speaking of those online designs, they usually came in two varieties: flimsy collapsable tables with no support structure, or large permanent tables with support around the outside of the plywood to prevent warping. Our project hoped to create the best of both worlds: a sturdy yet lightweight and portable table. Thus, we decided to use 1”x4” boards to create a frame around the outside of the table. Our design incorporates these boards structurally as well: when the table is opened, the hinge is attached to the 1x4s by the bottom allowing the boards to bear some of the weight that would otherwise be borne by the hinge. Thus, we were able to use a lightweight hinge design (24” piano hinge) that was inexpensive to purchase and easy to install.

Team Members:

Both of our team members worked hand in hand to complete the project together—from start to finish, we planned, built, and finished this table as a team. We worked hard to ensure the table was as strong, lightweight, and cost-effective as possible. This project would not have been possible without a group effort. The only separation in roles were as follows: Connor was responsible for the vast majority of drilling/screw insertion in the final construction, and Quin was responsible for the 3D modeling of our initial designs.

Connor Belcastro ’24 Quin Kirsten ’24

Difficulties Encountered/Changes Made:

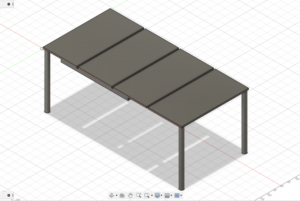

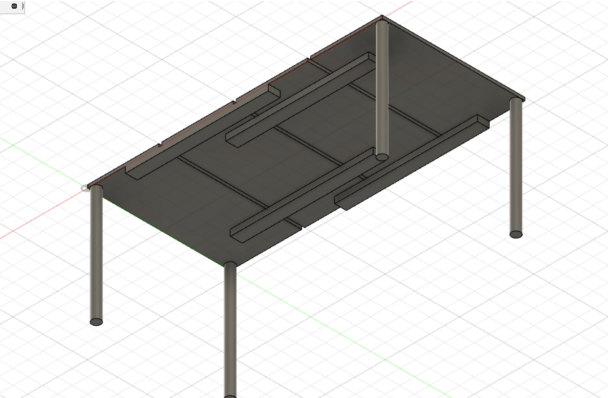

We encountered difficulties with our design in determining how to get the table to fold while still being solid enough for outdoor games. Our final design is significantly different from our original designs, as this was the only way to get it to be able to stand on its own. Our initial design, shown in the models below, consisted of four wooden panels that would fold together, and metal legs that would screw into each corner of the table. These designs could potentially have been effective, but the setup process necessary for using the table would be too extensive, and there are too many moving parts.

Because of these problems, we changed to the design below.

The above model is not complete though: it does not include our legs, and it shows two small hinges instead of the piano hinge that we ended up with. For the legs, we used three pieces of wood on each side of the table that folds into the table when needed and extends to support the table when it is set up. The hinges we used to fold the legs are a bit flimsy, however, and it can be difficult to get the legs to remain in place because of this. Though we have not yet done this, we intend to amend this issue by placing a small piece of wood that slides above the legs when it is folded and can be released to allow them to unfold. This will greatly increase the stability of our design. They can be seen (in the folded position) in the left image below. The right image shows our final piano hinge that connects the two sides of the table.

Our table’s design required a high degree of precision in both the cutting and assembling processes. Most outdoor games played on such tables require precise heights and dimensions for the table.

In addition, the edges of the table need to be supported to prevent warping, but there must not be any protrusions from underneath the table. Thus, it was important to cut our boards exactly to size within tight tolerances and assemble it similarly.

Because we spent so significantly on the plywood surface, we were forced to buy cheaper boards. We noticed that some of these boards arrived curved or otherwise warped. We had to assemble the table under tension in order to correct these warps and had to ensure that the warps faced inward so as not to protrude from the bottom of the table if the warping continued.

Given these difficulties, we have yet to paint and finish the surface of our table—we intend to do this as soon as possible to be ready to play outdoor games this summer! We intend to paint freehand on the surface of the table with acrylic paints (Quin is a stellar artist and will meet the challenge) and then cover the table with multiple thin coats of polyurethane. Thus, the table will look good and be ready to endure whatever outdoor elements might come its way.