Students:

Samuel Morton, Mateo Godoy, Whit Gamblin

Project Description

It all started with a movie. Last semester, we were living together in a house passing the time when we stumbled upon Alex Honnold’s documentary on how he climbed El Cap in Yosemite National Park without a rope. We were instantly obsessed with rock climbing. Unfortunately, none of us have cars at Princeton, so we are limited to the rock wall in the football stadium, but we are inspired nonetheless. Making a hang board for our CPS project is going to continue our journey of becoming great rock climbers until hopefully one day we can visit El Cap with the intention of climbing it.

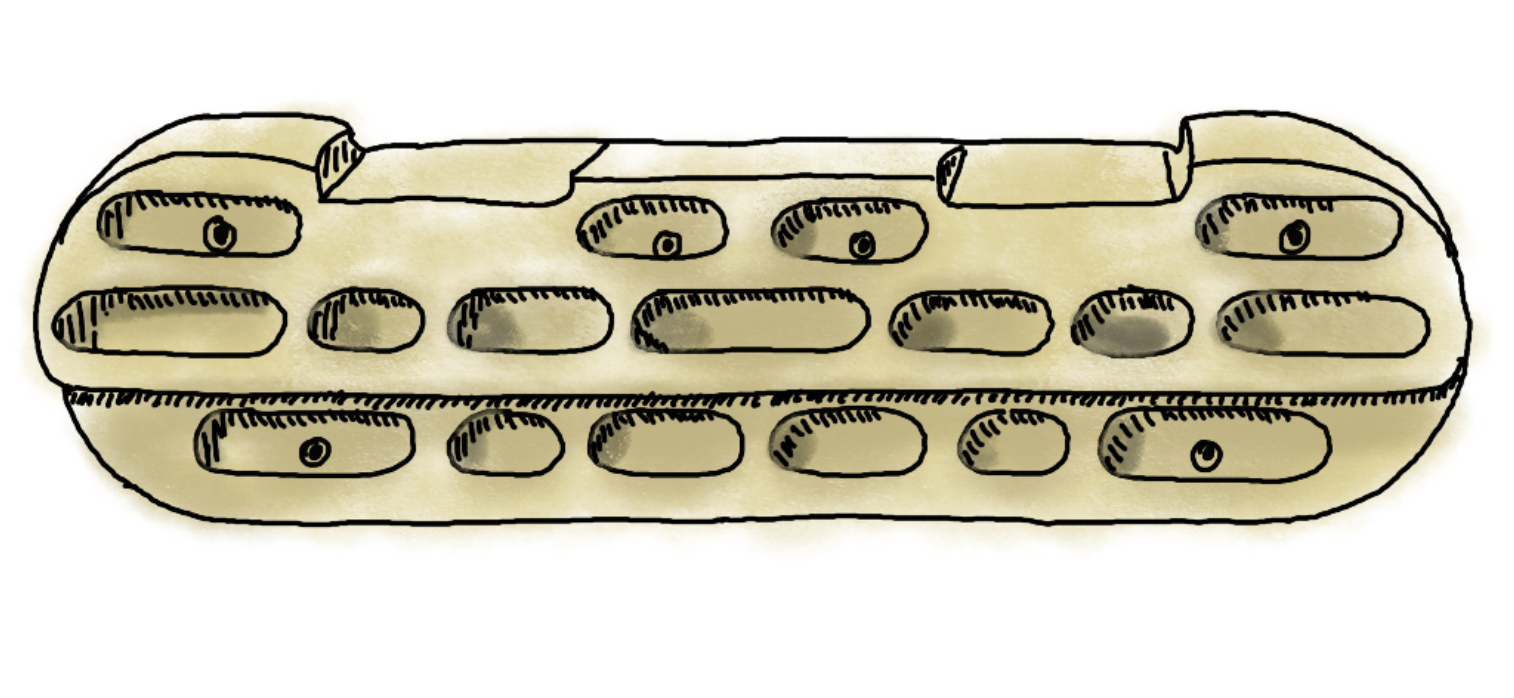

It all started with this:

Mateo is a bit of an artist, so he took the reins on designing a concrete sketch that we could model our idea after. This sketch was done on the iPad Pro using an Apple Pencil. The iPad was a great tool for getting some detail on our design and fleshing out what we did or did not want it to look like.

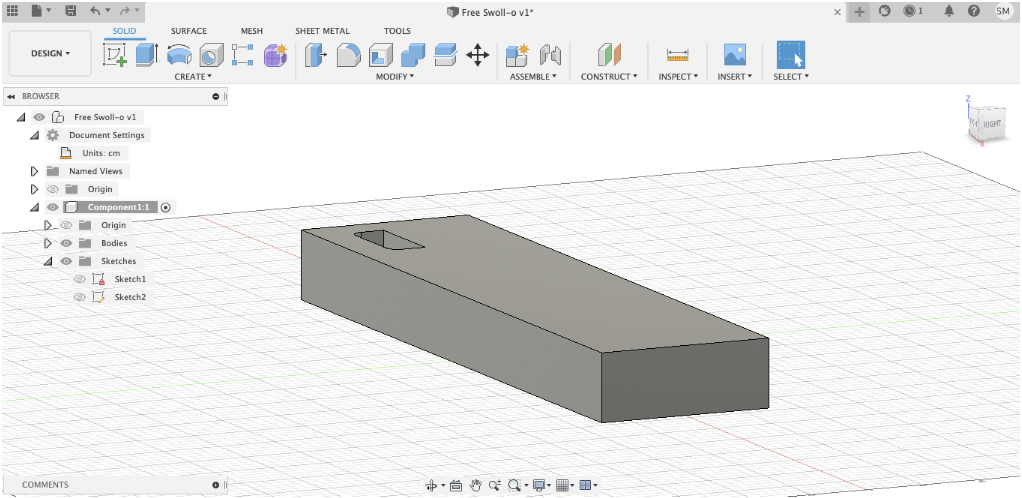

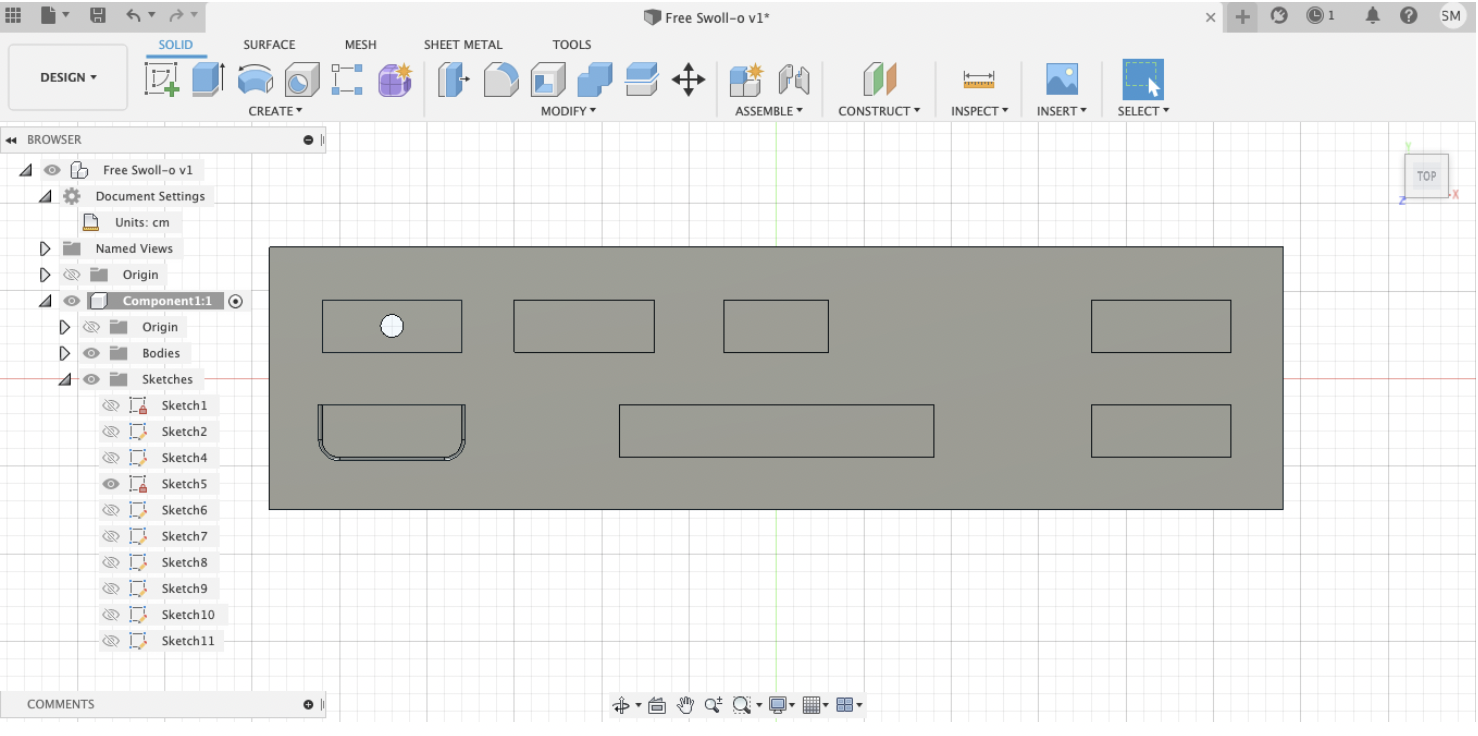

Whit did research on what type of wood would be best to use for our board and what screws we should use to mount it safely. He then took Mateo’s sketch and started a 3D model in Fusion 360 with proper dimensions and functional shape. He started to create handle holds on the board and came across 2 problems.

- The edges will be too sharp on the handle for proper grip

- Hang board holds generally have slanted angles to maximize grip potential

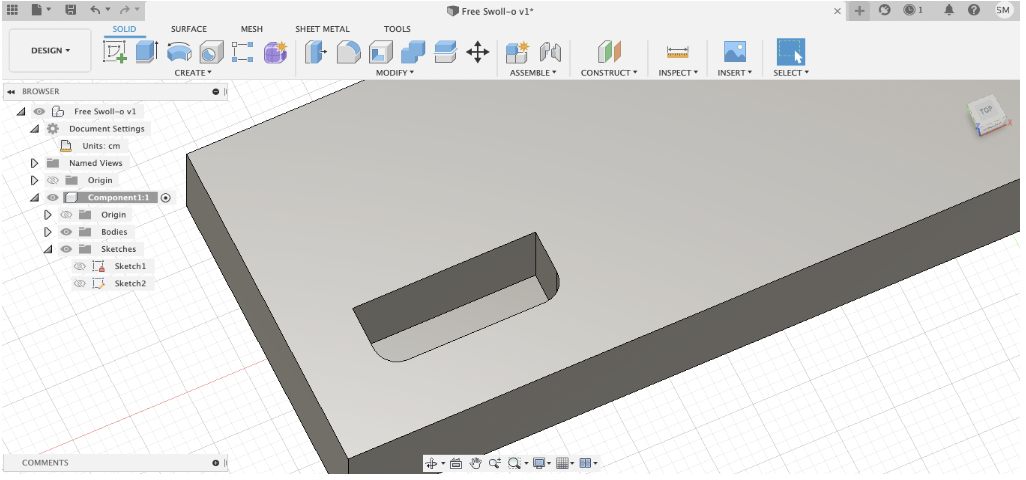

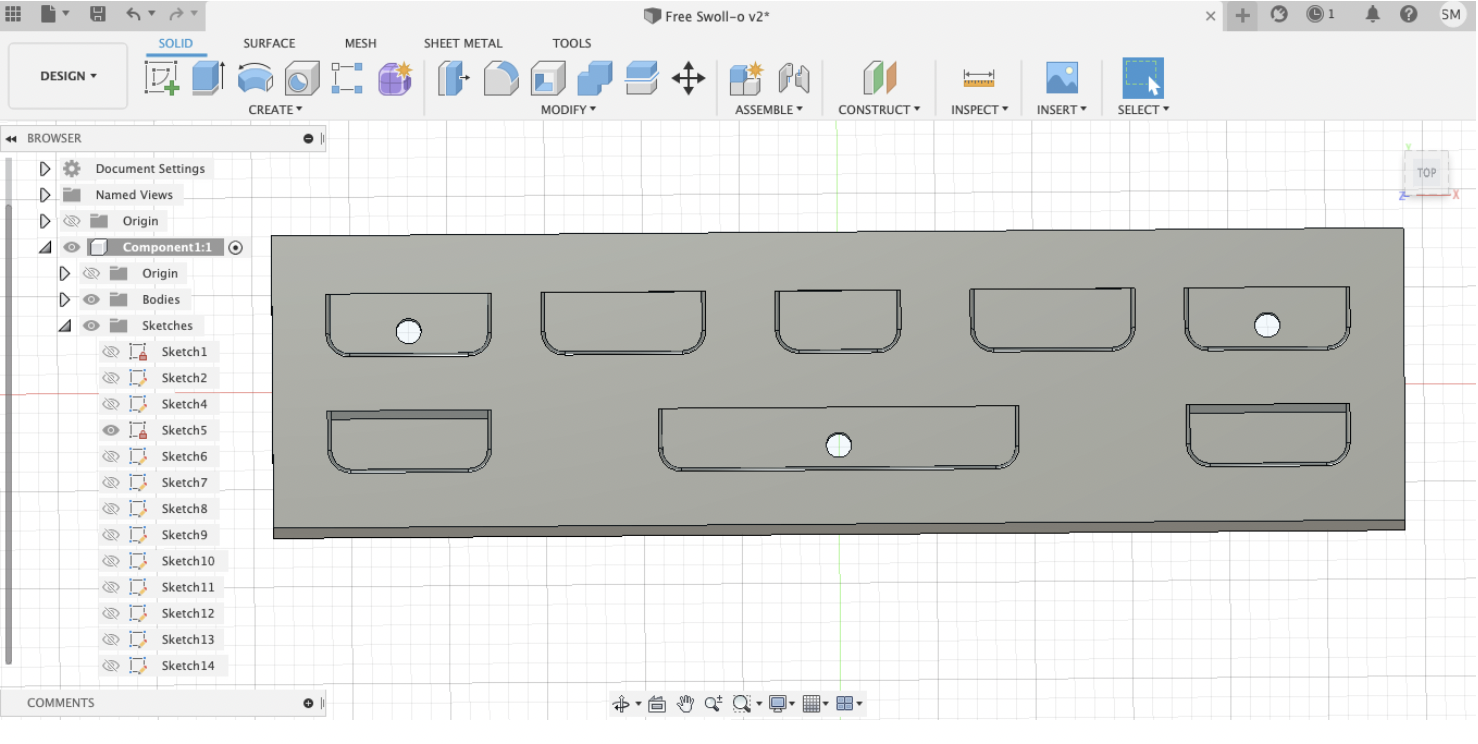

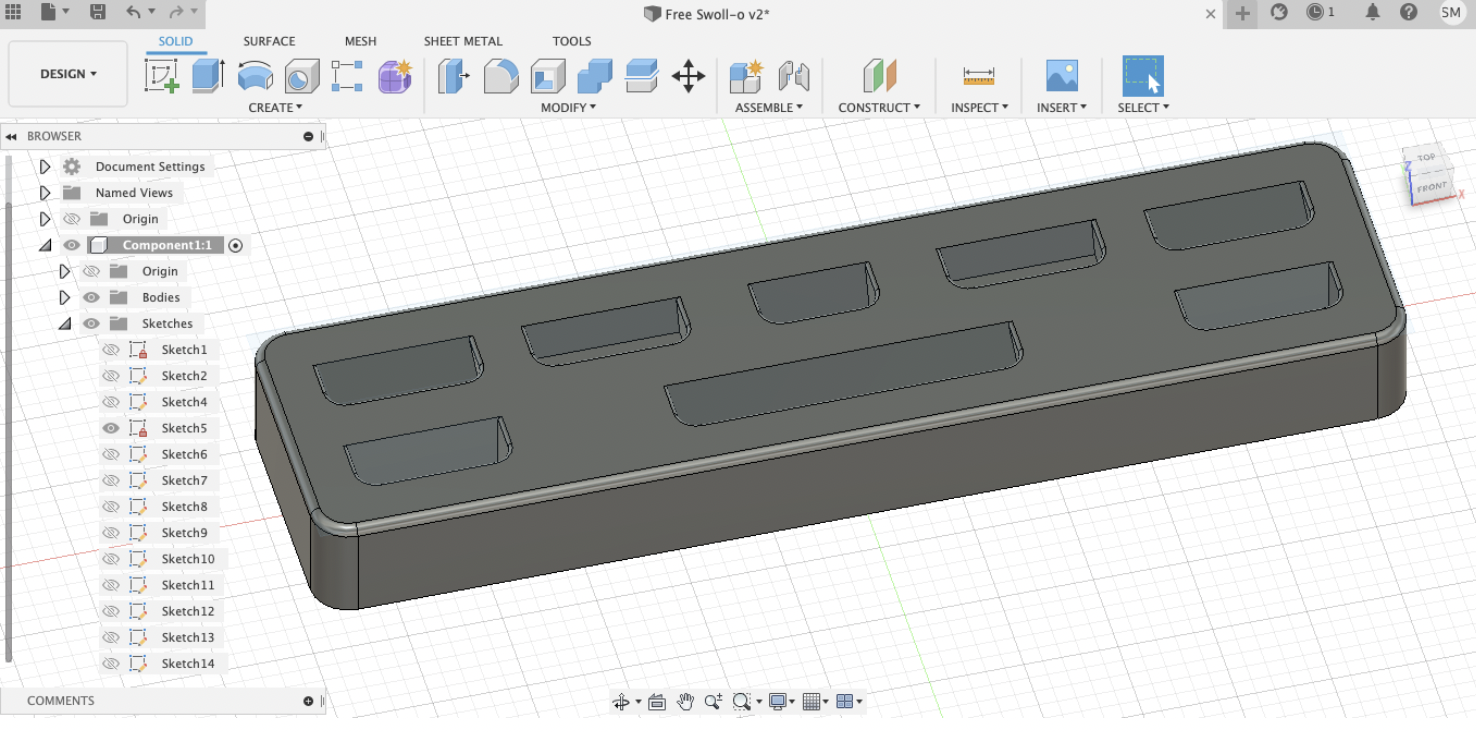

Sam did some Fusion 360 research and after looking through some tutorials figured out a way to fix both problems. To fix the edge, we could fillet each edge and corner on the board to give it a more rounded shape that is safer for the climber’s hands and adds an extra layer of complexity to the aesthetic of the design. Here is what the first finished hold looked like:

We used a 2mm radius on the edge that will prevent the climber from cutting their hand without taking away from the grip potential of the hold.

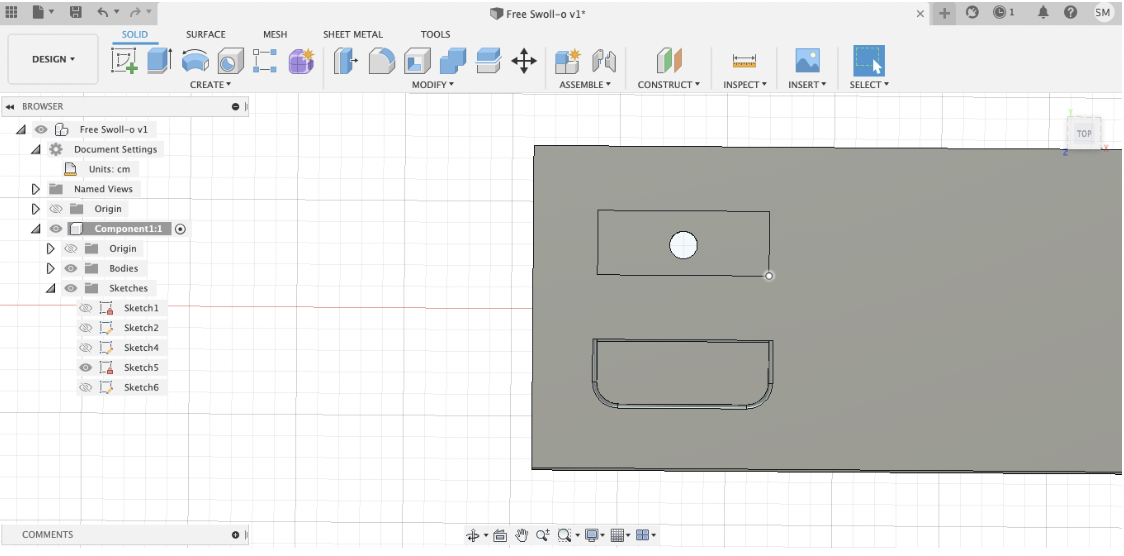

To fix the angle problem we extruded the holds in Fusion 360 at an angle to give them more leverage for the climber’s fingers.

.

.

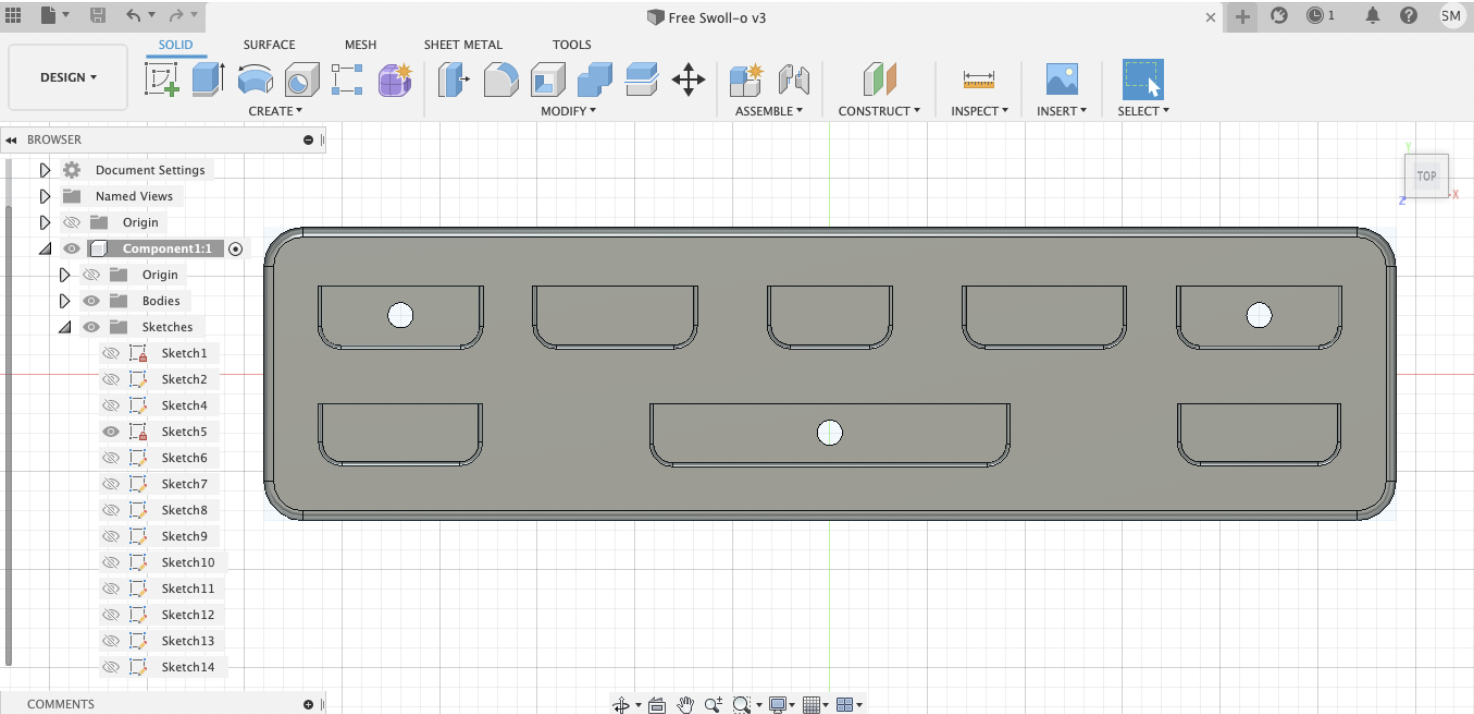

We also added some diversity between the holds so that some are meant for four fingers, some are meant for two or three fingers, some are deep for a full grip, and some are shallow for wants to be called a cremp, or short grip.

Next, we added the screw holes which are fit for half-inch bolts that are graded for at-home pull-up bars. We decided to make two holes at the top and one at the bottom for maximum sturdiness and stability.

Here is our completed model:

In the second semester, we are looking to complete our Fusion 360 design and prototype the holds on the wood we ordered. Potential design optimizations are only going to be recognized through trial and error so we are looking forward to utilizing smaller blocks of wood to gather data on which geometries and dimensions work best. We will also consider the best wood finishes to put on our design. We want the wood to be slip-resistant, so we are also considering methods in which to optimize friction within the holds. Usually, climbers will utilize chalk for enhanced grip but we like the idea of incorporating a design element that provides this functionality.