Magneto, Coil, Points, Headlamp, Horn

Team – Chris, Abbi

Asterisks (*) refer to notable physical components of our electrical system (read on).

Overview of Key Components

Alternator – This creates AC current from the mechanical energy of the engine.

Lighting – Headlamp (dip beam and high beam), tail lamp and stop lamp (brake light).

Energy Transfer Coil – Our ignition coil, which connects to the alternator and the spark plug.

Contact Breaker – Timed precisely with the pistons’ pumping, this component works with the ignition coil to create the voltage jump that causes the spark in the spark plug.

Engine Cut Out Switch – Essentially an emergency button, when pressed, this provides a route to ground so that current stops flowing through the contact breaker and the ignition coil, ending the sparking mechanism.

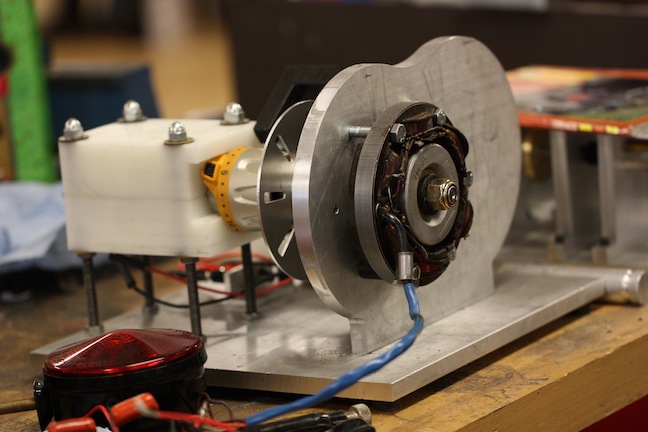

Tester

This is the Triumph electrical system tester. The stator and rotor are from a Triumph Tiger Cub.

Ignition System

Purpose: The ignition system creates the spark in the engine cylinder which ignites the fuel.

At a general level, the ignition system must generate a high voltage spark several hundred times a second at exactly the right time in the engine cycle. Creating a spark across the gap in the spark plug requires about 10,000 volts. Our system must be able to repeat this several million times without maintenance and in a variety of conditions.

Our system is called an Energy Transfer Ignition System and consists of an alternator, ignition coil, points, points cam, capacitor, and spark plug. Where other systems use a battery and must then use a rectifier to covert the AC current generated by the alternator to DC current, our system operates entirely on AC current. (More details about other systems below)

Alternator:

The alternator consists of a rotor and stator windings. The rotor is a six-pole magnet which spins and, through electromagnetic induction, generates current in the six stator windings.

Ignition Coil:

The ignition coil is a step-up transformer which generates the high voltage necessary for the spark plug. Voltage generated by the alternator flows through the primary coil of the transformer.

Points:

The points serve as the switch that ultimately creates a sufficient voltage drop to create a spark in the spark plug. When the points open, a current flows through the primary coil, and causes the flux to change. This large change in flux induces a magnetic field within the coils of the solenoid. Thus a large voltage is generated inside the primary coil. The transformer inside the ignition coil then ‘step-up’s this voltage to several thousand kilo-Volts.

Points Cam:

This is a ramp of sorts that spins and opens and closes the points.

Centrifugal Advance Mechanism:

As the piston spins faster, the fuel in the engine cylinder has less time to burn. This mechanism advances the timing of the spark as rpm increases so that the fuel has enough time to burn such that there’s maximum pressure when the cylinder is at the top. On the sides of the spinning shaft, there are free weights which push to the sides as rpm increases (centrifugal motion). These weights pull on springs which twist the points cam an additional amount.

Capacitor:

A capacitor is an electric component that stores charge. When the points open, the capacitor collects charge and prevents current from arcing across the points.

Spark Plug:

This is where the spark in the engine is generated. The high voltage generated in the secondary coil of the transformer is high enough to jump the gap between the spark plug.

Other Systems and Advantages:

Battery-coil Ignition System:

Other systems typically use batteries. In a battery-coil ignition system, current flows through the primary winding until the points open. This large, sudden drop in voltage creates a back voltage in the primary winding due to the massive change in flux. Thus, this voltage is then stepped-up in the ignition coil before going to the spark plug.

Some advantages in our system include (1) a battery and separate generating system are not necessary. (2) Simple, elegant construction.

Electronic Ignition:

Sometimes called a capacitor discharge system, this ignition system has a large capacitor which is charged with direct current to a few hundred (100-400) V. These systems use more advanced electrical components, including diodes, thyristers, and transistors.

Some advantages of this system include the lack of points (points burn out or misadjusted), ignition timing doesn’t change, higher secondary voltages are possible, electronic switching is more effective, and the sealed units provide a moisture-free environment.

Source: Lear, George. Motorcycle Mechanics.